SCANMIN KUTSCAN ANALYSER

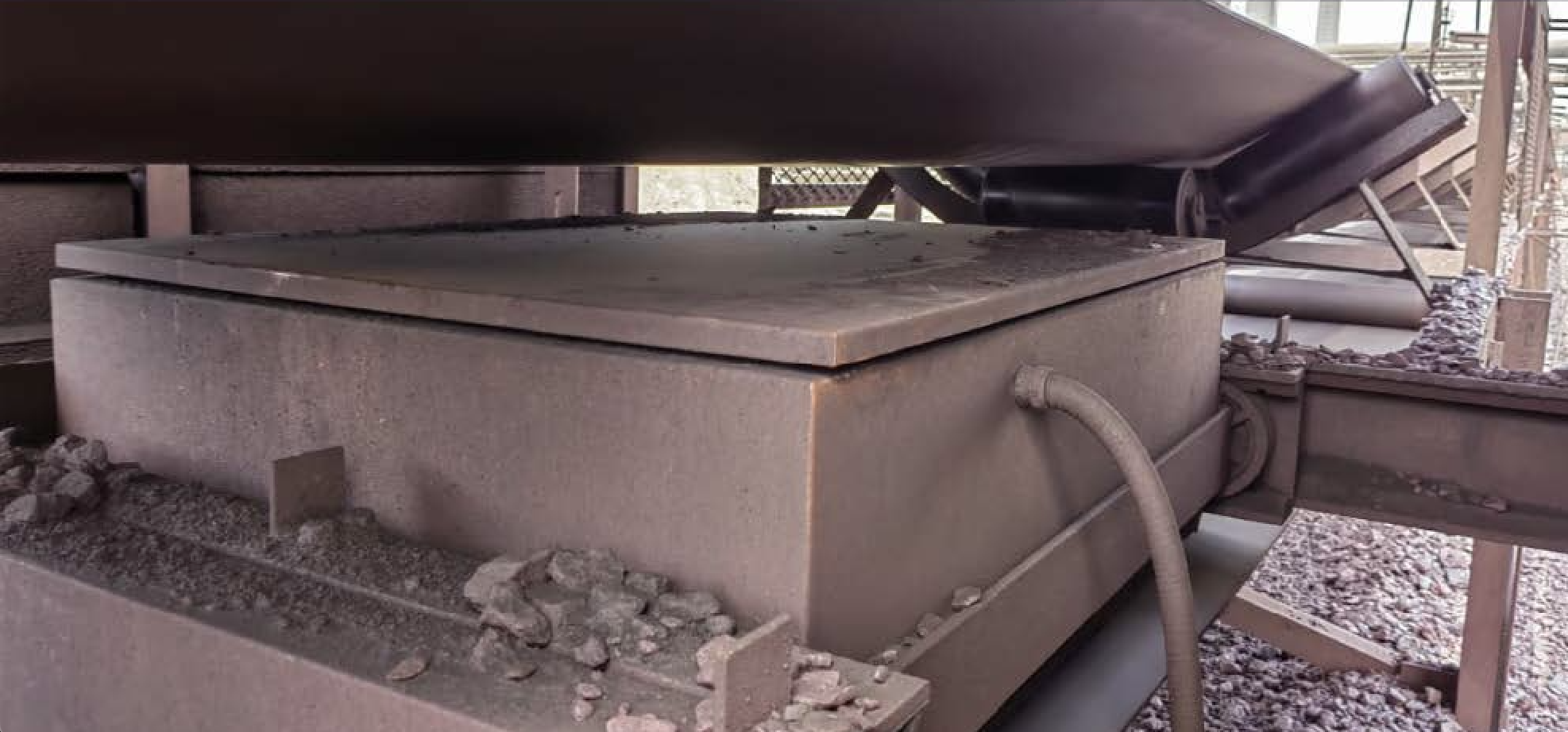

The ScanMin KUTScan analyser can measure the bulk material on a conveyor belt

It is a rugged design that can operate in most industrial environments. The analyser has a wide range of applications.

Results can assist operators with:

- ore grade control

- bypass control

- contamination monitoring (e.g. Potassium concentration to smelters) Real time elemental analysis enables active process

Possible applications

Coal mineral matter (Ash)

- Determination of quality by reporting CV and Ash content

- Moisture as an optional extra

Mineral applications

- Direct measurement of K, U and Th

- Other minerals determined by direct correlation to above

Key features

- No isotope required – no RPO administration

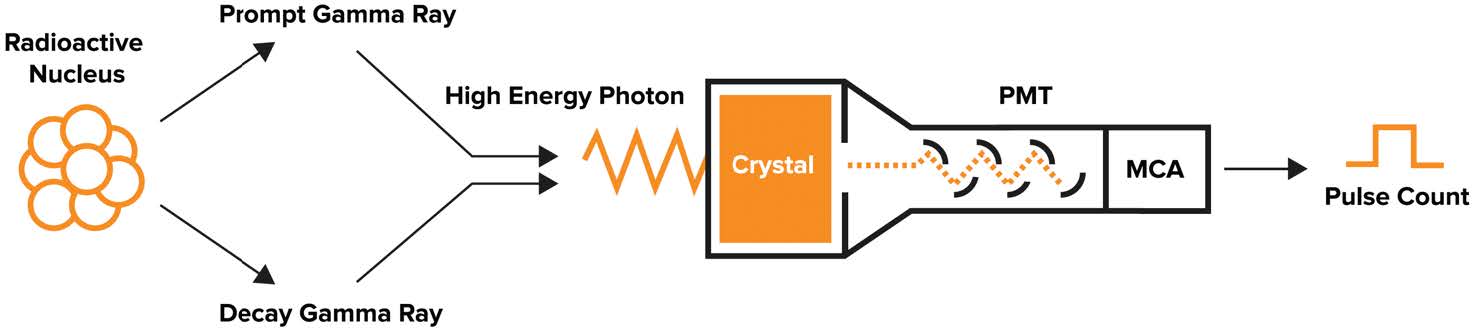

- Latest digital MCA and detector technology

- Variable mass flow compensation

- Rugged design

- Few moving parts • Low maintenance – No Wear parts or consumables

- No Radiation –Safe for personnel

- Easy to install

SPECIFICATIONS

| Conveyor Width: | Up to 2100mm |

| Bed Depth: | Typical 100mm up to 350mm |

| Material Size: | Up to 300mm |

| Weight: | 2200kg (approximate) |

| Electrical: | 110VAC – 240VAC (400VA) |

| Inputs: | Belt speed and mass |

| Outputs: | EthernetIP, Modbus, Profibus, OPC etc. Analysis results and status data are transmitted to the plant via data communication protocol or interface. The system is compatible with most standard industrial systems. |

| Enclosure: | IP65. Zone21/22 also available |