COAL

Coal Washing

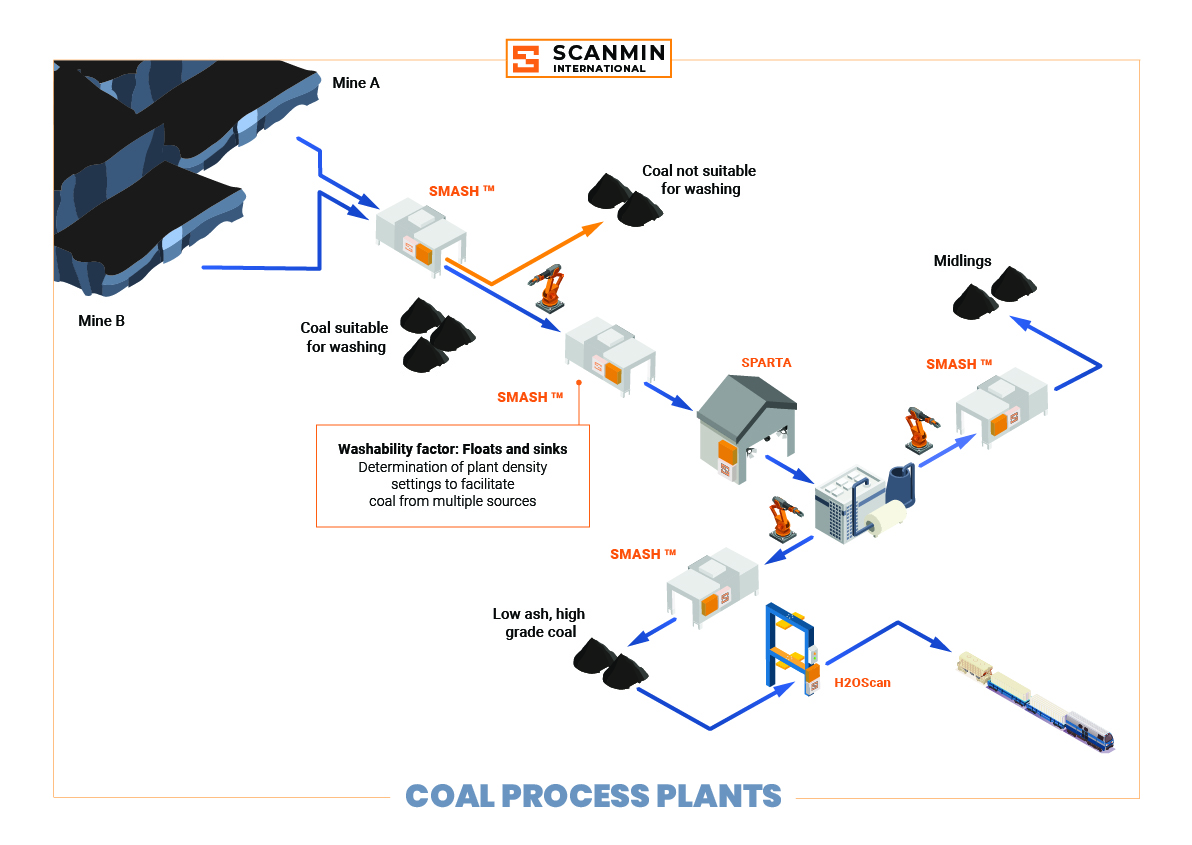

Coal is a combustible sedimentary deposit predominantly composed of carbon. Mined coal may contain be a complex mix of physical properties including portions of inorganic or waste material. Coal washing is used to ensure coal are free from impurities, or to differentiate between the various grades of coal.

Coal washing uses two main processes to separate different materials

- Density separation – Inorganic elements typically have a higher SG

- Froth Flotation- lighter Coal particles float to the top of a flotation cell

ScanMin’s SMASH™ Analyser measure both Organic and Inorganic material and therefore can measure before and after washing processes to give a holistic view of the process

SMASH™ Measurement enable plant operators to in Coal processing to characterize the type and number of impurities and provide the ability to monitor and optimize coal for

- Quality control – ensure correct grades are supplied

- Blending –stockpiles with similar GCV or Higher Heating value (HHV)

- Contractual compliance – export of coal where sampling is not representative enough of batch quality

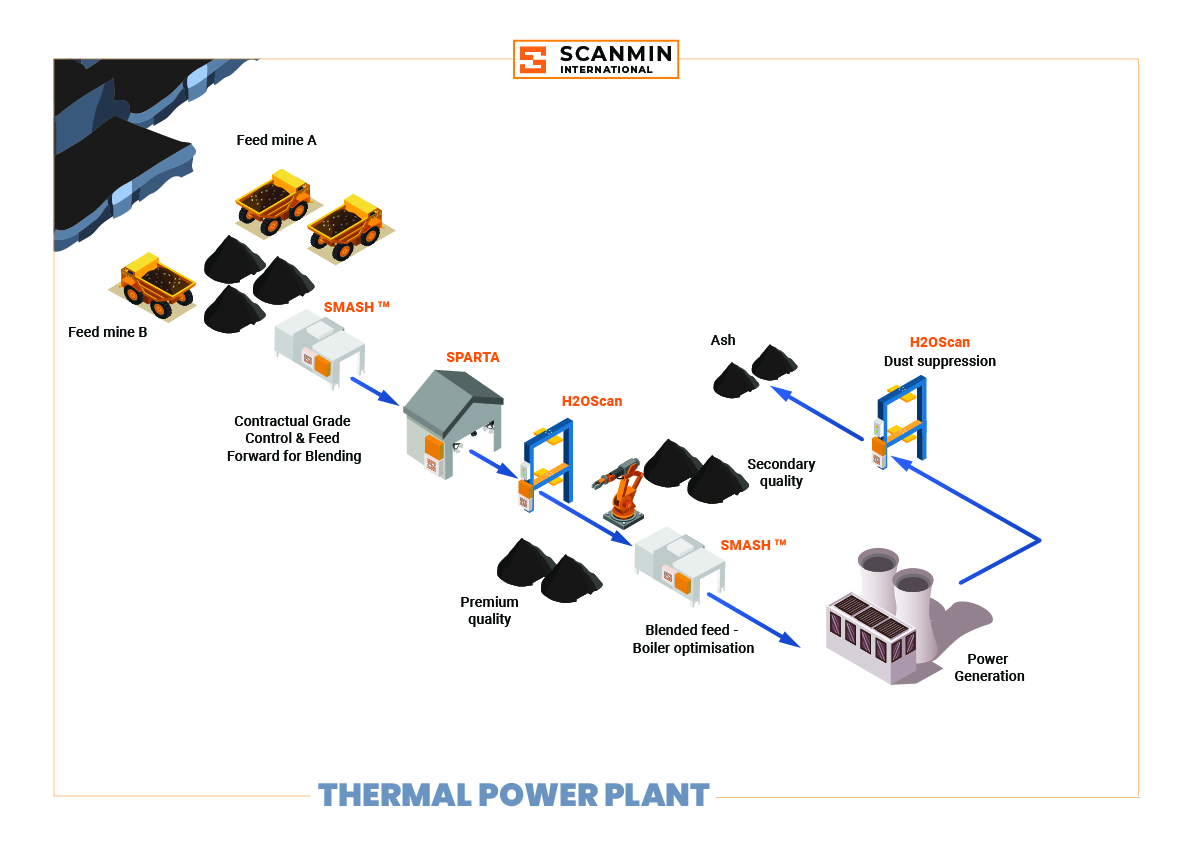

Coal Power Generation

Energy content of coal is given in terms of Kilojoules (kJ) per Kilogram (kg) of coal (GCV)or the Higher Heating value (HHV) of coal.

In Coal fired power plants the information obtained from ScanMin’s SMASH™ GADRA Analyser in the coal feed to the boiler provides

- Calorific Value (CV)

- Ash content

- Sulphur Content

Engineers and operators can use this information to

- Optimize Boiler and Flame burn and power output

- Energy calculation

- Emissions management – control of the sulfur dioxide, nitrogen oxides,

Mineralogy

ScanMin can in addition to:

- Elemental concentration

- Total moisture

- Volatile matter

- ROM feed grade

Also provide Mineralogy identification of the different types of coal

This is an important parameter as although coal types may have the same calorific value (CV), differences in mineralogy may mean that burn rates and ash contents are different.

Understanding these parameters before feeding boilers or smelters, will allow reduced risk and allow optimization of these processes

ScanMin values quality and has an IECEx accredited Quality Management System. Further to this the ScanMin SMASH™ Analyser is IECEx accredited and is designed for operation in combustible dust Zone22 areas with focus on: .

- Zone22 flameproof glands and cabinets are used

- Selection of IP65 equipment

- Paint is non-conductive and IECEx approved

- Attention to earthing and wiring