MINERALS

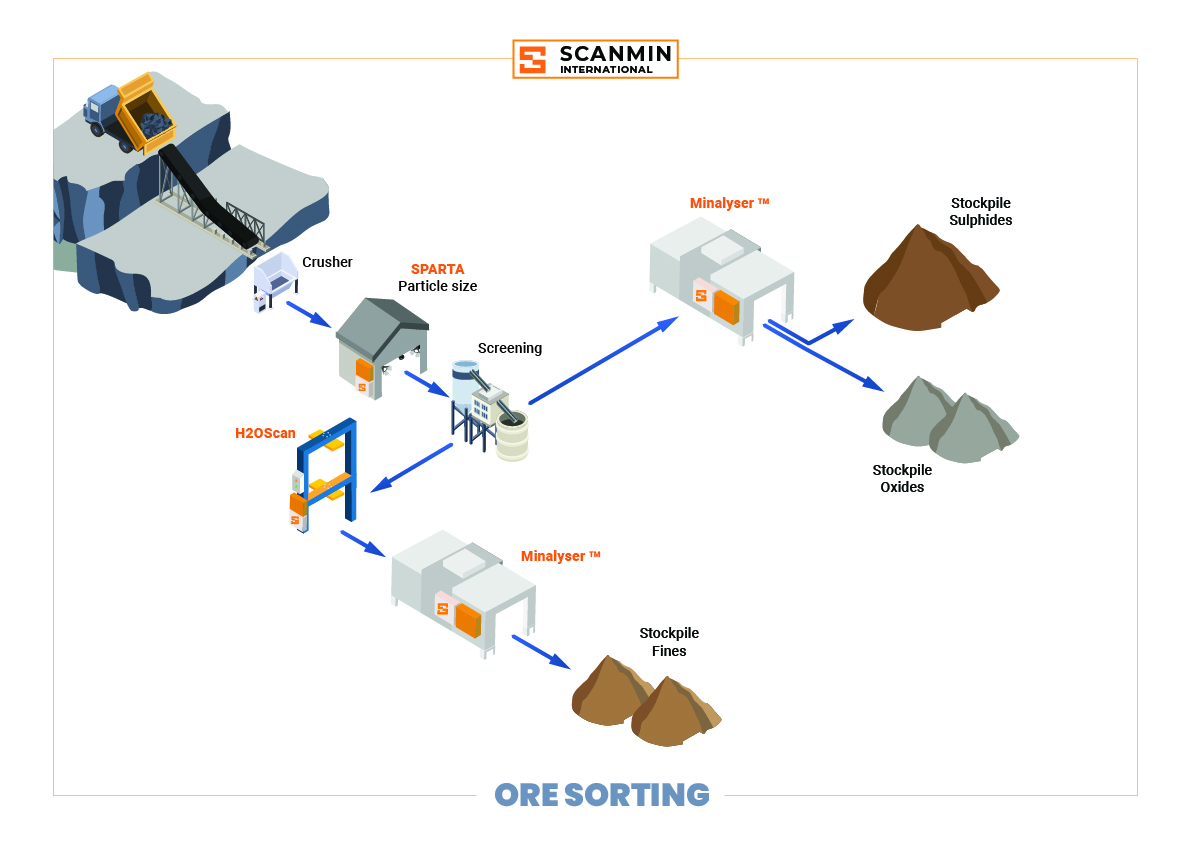

Efficient Mineral beneficiation processes are required to refine mined ore to high value concentrates. Real time measurement allows the identification of valuable ore components and gangue; and the ratios between these, in feedstock material

Comminution

As comminution circuits are some of the biggest energy and cost drivers in mining and processing, there is significant value in optimising these processes.

The use of real-time online information that provide engineers the tools to:

1. Optimise comminution processes.

- By identifying waste in the feedstock stage, waste can be returned to the pit without processing the waste and incurring costs.

- Milling can be specific to the mineral, and not simply based on the elemental concentration

2. Classify material for elemental concentration, particle size or mineralogy

This provides feed forward control for downstream processes allows development of accurate and relevant stockpiling. Accurate stockpiling allows transparent financial reporting

Mineralogy

Many downstream processes are affected by mineralogy of the feedstock, examples include:

- In copper, various clays affect the flotation process in different ways.

By understanding the clay mineralogy, the information can be used to provide feedforward control parameters to minimise the impact

- Understanding the mineralogy provide insight into textural relationships about grain size, particle size after crushing and the amount of liberation required for optimising downstream processes

Pyrometallurgy

SCANMIN’s Minalyser can measure organic and inorganic material.

This facilitate the unique ability to provide valuable information for Pyrometallurgical processes where Concentrates, Reductants and Fluxes can all be measured with a single analyser.

Ferrochrome, mineral sands and other pyrometallurgical processes can benefit from understanding and adjusting the precise feed to their smelter operations