SPARTA

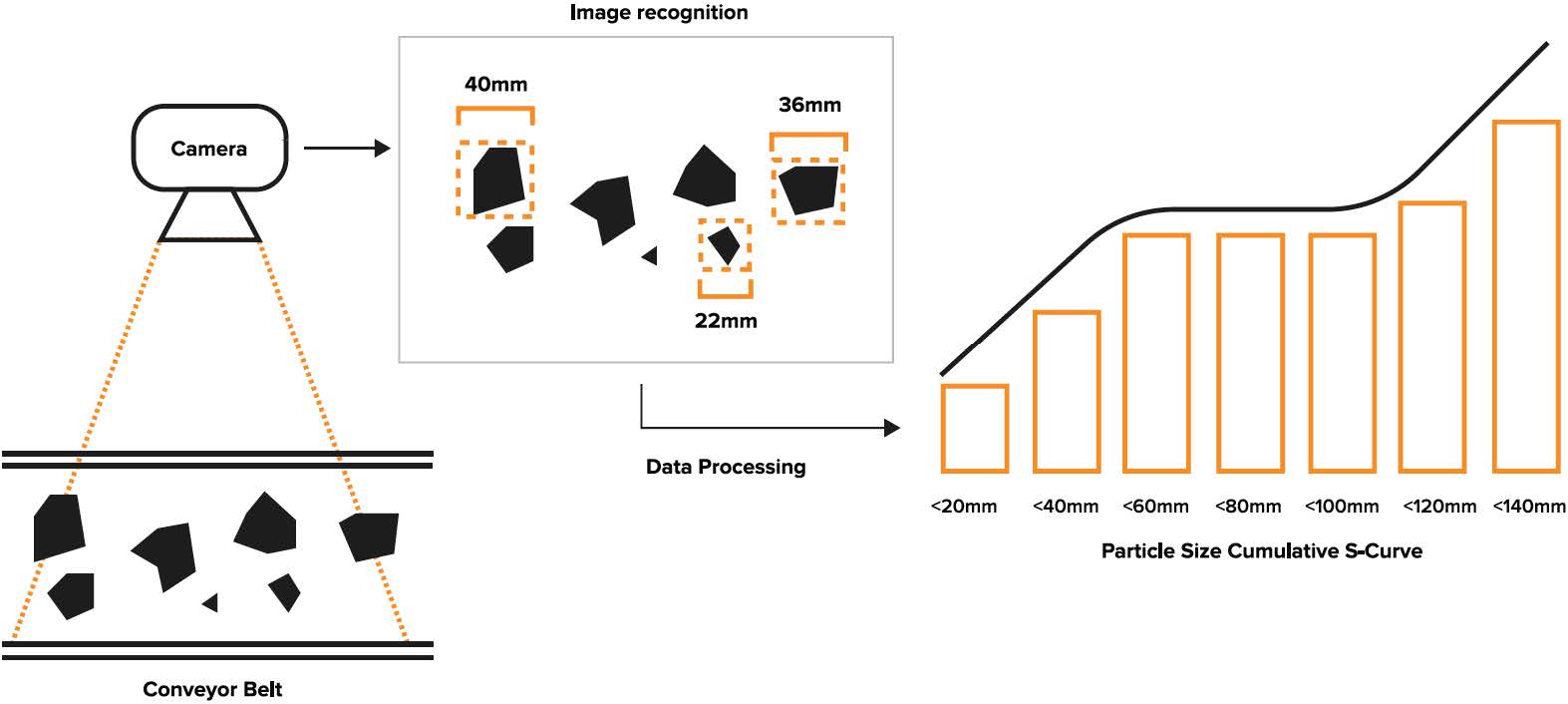

The SPARTA analyser is especially useful in material comminution circuits

Results are used by plant managers to ensure product has been sufficiently crushed as well as stop crusher wear from going unnoticed. Results can also be fed into a control loop to control crusher apertures when dealing with diverse materials of different crushability. This saves on plant damage and downtime.

Results reporting

Results are accessed either directly from a SQL database or from an excel spreadsheet. The appropriate S-curves and histograms are made available to the client. Data is analysed in real-time and available instantaneously. Product photos are also stored allowing for later checking and verification.

Technology

POSSIBLE APPLICATIONS INCLUDE:

- Mill feed monitoring

- Crusher wear detection

- Increased efficiency

- Improved mineral extraction

- Closed loop control

- Performance monitoring

Key features

- Rapid online results

- Continuous analysis

- Crusher performance monitoring

- Final product control

- Rugged design and construction

- Remote access and data availability

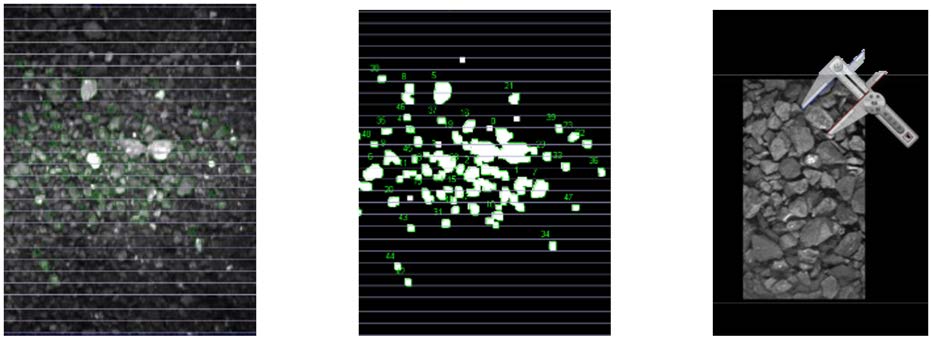

Calibration

Calibration is done by measuring known material via a virtual calliper

SPECIFICATIONS

| Conveyor Width: | Will fit almost any conveyor application |

| Bed Depth: | Up to 400mm |

| Material Size: | 12mm – 300mm |

| Electrical: | 110VAC – 240VAC (1500VA) |

| Inputs: | Belt run. |

| Outputs: | EthernetIP, Modbus, Profibus, OPC etc. Analysis results and status data are accessed on the industrial processor. Plant interface protocols are also available. |

| IP Rating: | IP65. |