APPLICATIONS

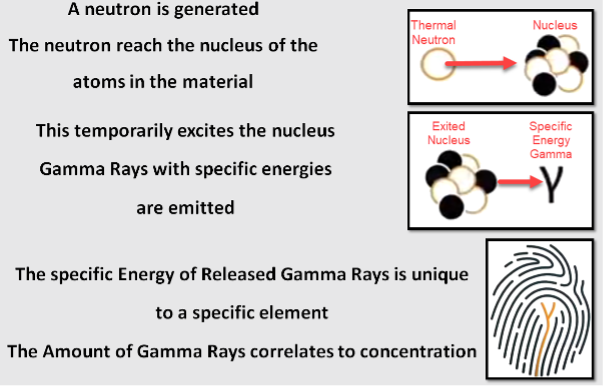

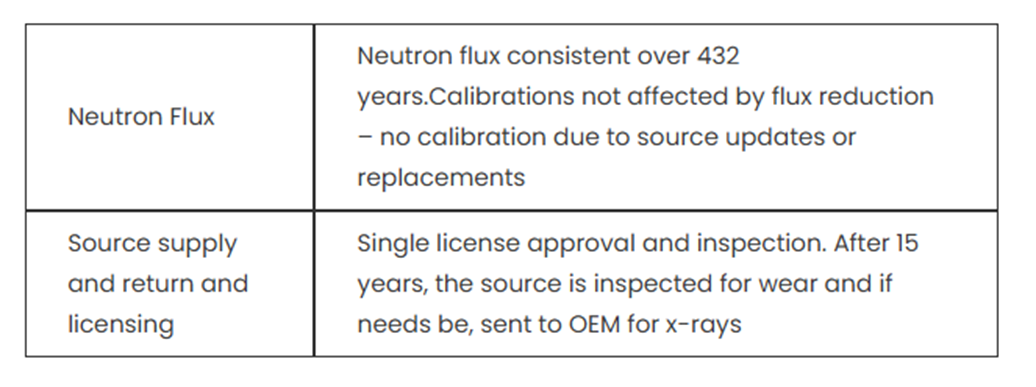

Scanmin’s Gamma Activation Dual Response Analysis (GADRA) technology utilises a high energy AMBE 241 Source with an half-life of 432 years, Ambe sources does not require

• Any top ups

• Source replacement in the lifetime of the analyser

• Ambe sources provide high energy system that allows measurement of two physical reactions

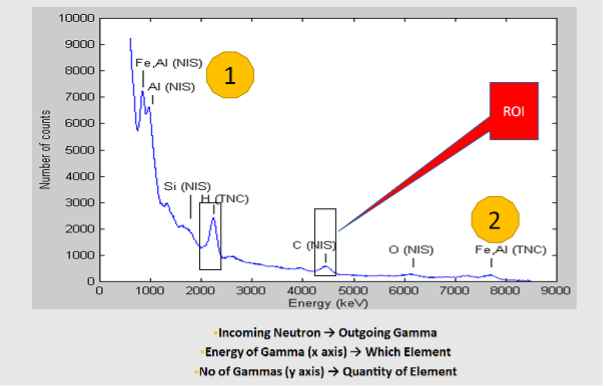

• Neutron Inelastic Scatter

• Thermal Neutron Capture

Compared to most industry systems, measurement of NIS provide an additional Region of Interest (ROI)– and the calibration department can select which ROI is the most on-target for a particular application

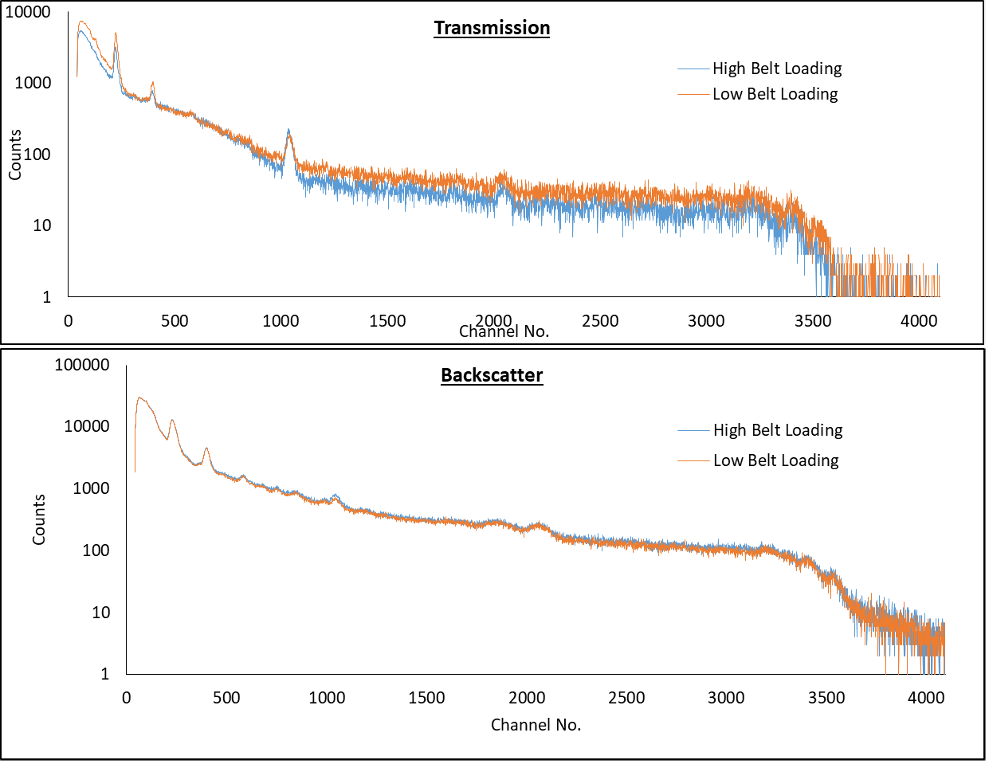

The back scatter detector is unaffected by mass variation on the conveyor

Coal Industries

Ash

CV

Volatile matter

Total moisture

Other ash elements

Quality Control

Blending

Contractual Compliance

Stock pile management

Boiler control

Energy calculation

Emissions management

Mineral Industries

Minerals processing – Elemental Analysis

Minerals processing – Contractual compliance

Pyrometallurgy – Blast furnace control

Pyrometallurgy – Improved performance

Cement – Raw mix control

Cement – Quality assurance

Phosphate – Grade control

Phosphate – Stock pile control

Chemicals – Improved efficiency

Chemicals – Valuable insight

Typical Analytes

Element & Indices (Main)

- Hydrogen

- Carbon

- Nitrogen

- Oxygen

- Chromium

- Magnesium

- Aluminium

- Iron

- Silicon

- Titanium

- Manganese

- Calcium

- Ash

- Calorific Value

- Sulphur

- Moisture

Field Proven Instruments provide measurements for:

COAL